The size of the stepper motor for a CNC Router depends on several factors, including load requirements, speed and accuracy requirements, power requirements, and cost. Common stepper motor sizes for CNC Routers include NEMA 17, NEMA 23, and NEMA 34, with NEMA 17 being the smallest and most cost-effective option and NEMA 34 being the largest and most powerful option. It is important to consider these factors and choose a stepper motor that is capable of meeting the specific requirements of your CNC Router.

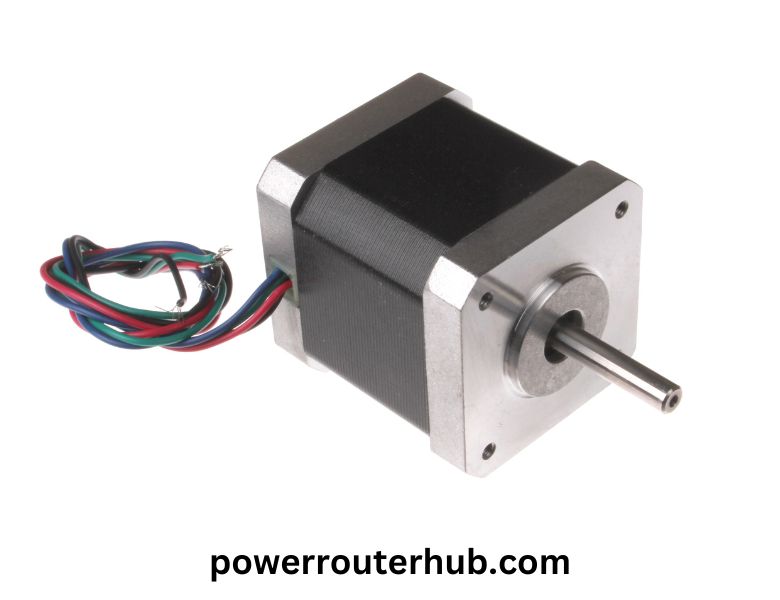

CNC (Computer Numerical Control) Routers are computer-controlled machines that are used to carve or cut materials into complex shapes. They are widely used in a variety of applications, including woodworking, plastics, and metal fabrication. The heart of a CNC Router is its control system, which is responsible for executing the movements of the machine’s cutting tools. One of the key components of the control system is the stepper motor.

The stepper motor is a crucial component in the control system of a CNC Router. It converts digital signals from the control system into precise physical movements of the cutting tool. Choosing the right size stepper motor for your CNC Router is essential for ensuring the machine’s accuracy, speed, and overall performance. A stepper motor that is too small for the machine’s requirements will struggle to perform the required movements, while a stepper motor that is too large will be unnecessarily expensive and wasteful.

The purpose of this blog post is to provide a comprehensive guide on how to choose the right size stepper motor for a CNC Router. The post will cover the factors that need to be considered when choosing a stepper motor, including load requirements, speed and accuracy, power requirements, and cost. The post will also provide tips for choosing the right stepper motor, as well as a brief overview of common stepper motor sizes for CNC Routers.

Understanding Stepper Motors

Stepper motors are electric motors that are designed to rotate in precise steps. Unlike DC or AC motors, which rotate continuously, stepper motors move in individual steps, allowing for precise control over the motor’s position and speed. This makes them ideal for applications where precise control is required, such as in CNC Routers.

There are two main types of stepper motors: unipolar and bipolar. Unipolar stepper motors have a single winding with a center tap, while bipolar stepper motors have two separate windings that are not connected in the center. Bipolar stepper motors are typically more precise and have better torque performance than unipolar stepper motors, making them the preferred choice for most CNC Router applications.

In a CNC Router, the control system sends digital signals to the stepper motor, which then rotates the cutting tool in precise steps. The number of steps required to rotate the cutting tool by a certain amount is determined by the control system’s software. The stepper motor’s precise control over the cutting tool’s position and speed allows for accurate cutting and shaping of the material being worked on.

By accurately controlling the movements of the cutting tool, the stepper motor enables the CNC Router to produce precise cuts and shapes with high accuracy and repeatability. This is essential for achieving the desired results in applications such as woodworking, metal fabrication, and plastics manufacturing.

Factors to Consider When Choosing a Stepper Motor for CNC Routers

A. Load Requirements

The first factor to consider when choosing a stepper motor for a CNC Router is the load requirements. The load requirements refer to the amount of force required to move the cutting tool and the material being worked on. This will depend on the size and weight of the cutting tool and the material being worked on. A stepper motor that is too small for the load requirements will struggle to perform the required movements, leading to reduced accuracy and poor performance.

B. Speed and Accuracy

Speed and accuracy are two of the most important factors to consider when choosing a stepper motor for a CNC Router. The stepper motor needs to be able to rotate the cutting tool quickly enough to meet the desired cutting speed, while also maintaining the required level of accuracy. The accuracy of the stepper motor is typically measured in steps per revolution, with higher-precision stepper motors having a higher number of steps per revolution.

C. Power Requirements

The power requirements of the stepper motor will depend on the size and weight of the cutting tool and the material being worked on, as well as the desired speed and accuracy. Larger stepper motors will typically require more power, but will also be able to produce more torque and handle heavier loads. It is important to choose a stepper motor with the right power requirements for your CNC Router to ensure that it can handle the desired cutting speed and accuracy.

D. Cost

Cost is always a factor to consider when choosing any type of machinery or equipment, including stepper motors for CNC Routers. The cost of a stepper motor will depend on a number of factors, including its size, accuracy, and power requirements. Larger stepper motors with higher accuracy and power requirements will typically be more expensive than smaller, less accurate stepper motors. It is important to strike a balance between cost and performance when choosing a stepper motor for a CNC Router.

Finally, choosing the right size stepper motor for a CNC Router involves considering a number of factors, including load requirements, speed and accuracy, power requirements, and cost. The stepper motor is a crucial component in the control system of a CNC Router, and choosing the right one is essential for ensuring the machine’s accuracy, speed, and overall performance.

Sizing a Stepper Motor for Your CNC Router

Sizing a stepper motor for your CNC Router requires careful consideration of several key factors, including load requirements, speed and accuracy, power requirements, and cost. The following are the steps to follow when sizing a stepper motor for your CNC Router.

Determine Load Requirements

The first step in sizing a stepper motor for your CNC Router is to determine the load requirements. The load requirements refer to the amount of force required to move the cutting tool and the material being worked on. This will depend on the size and weight of the cutting tool and the material being worked on. It is important to choose a stepper motor that is capable of handling the load requirements of your CNC Router to ensure accurate and reliable performance.

Consider Speed and Accuracy Requirements

The next step in sizing a stepper motor for your CNC Router is to consider the speed and accuracy requirements. The stepper motor needs to be able to rotate the cutting tool quickly enough to meet the desired cutting speed, while also maintaining the required level of accuracy. The accuracy of the stepper motor is typically measured in steps per revolution, with higher-precision stepper motors having a higher number of steps per revolution.

Determine Power Requirements

Once you have considered the speed and accuracy requirements, you need to determine the power requirements of the stepper motor. The power requirements of the stepper motor will depend on the size and weight of the cutting tool and the material being worked on, as well as the desired speed and accuracy. It is important to choose a stepper motor with the right power requirements for your CNC Router to ensure that it can handle the desired cutting speed and accuracy.

Consider Cost

Finally, you need to consider the cost of the stepper motor. The cost of a stepper motor will depend on a number of factors, including its size, accuracy, and power requirements. Larger stepper motors with higher accuracy and power requirements will typically be more expensive than smaller, less accurate stepper motors. It is important to strike a balance between cost and performance when choosing a stepper motor for your CNC Router.

See Also: Wood Router Buying Guide

Common Stepper Motor Sizes for CNC Routers

There are several common stepper motor sizes for CNC Routers, each of which is designed to meet different requirements in terms of load, speed, accuracy, power, and cost. The following are the most common stepper motor sizes for CNC Routers:

NEMA 17

The NEMA 17 stepper motor is one of the most commonly used stepper motors for CNC Routers. It is a small and compact motor that is ideal for use in small to medium-sized CNC Routers. The NEMA 17 stepper motor typically has a holding torque of between 40 and 60 Ncm, making it suitable for light to medium loads.

NEMA 23

The NEMA 23 stepper motor is a larger and more powerful motor than the NEMA 17. It is ideal for use in medium to large-sized CNC Routers, and is capable of handling heavier loads and producing more torque. The NEMA 23 stepper motor typically has a holding torque of between 60 and 120 Ncm.

NEMA 34

The NEMA 34 stepper motor is the largest and most powerful of the common stepper motor sizes for CNC Routers. It is ideal for use in large CNC Routers, and is capable of handling very heavy loads and producing large amounts of torque. The NEMA 34 stepper motor typically has a holding torque of over 120 Ncm.

Conclusion

When choosing a stepper motor size for your CNC Router, it is important to consider the load requirements, speed and accuracy requirements, power requirements, and cost. The NEMA 17 stepper motor is the most cost-effective option, but may not be suitable for larger and more demanding CNC Routers. The NEMA 23 and NEMA 34 stepper motors are more powerful and accurate, but are also more expensive.

In conclusion, choosing the right size stepper motor for your CNC Router is essential for ensuring the machine’s accuracy, speed, and overall performance. The size of the stepper motor depends on several factors, including load requirements, speed and accuracy requirements, power requirements, and cost. Common stepper motor sizes for CNC Routers include NEMA 17, NEMA 23, and NEMA 34, with NEMA 17 being the smallest and most cost-effective option and NEMA 34 being the largest and most powerful option.

When choosing a stepper motor, it is important to carefully consider these factors and choose a stepper motor that is capable of meeting the specific requirements of your CNC Router. By following these guidelines, you can ensure that you choose the right size stepper motor for your CNC Router, which will help to ensure the machine’s accuracy, speed, and overall performance.