A router table is a versatile tool that is commonly used in woodworking for a variety of tasks such as routing, shaping, and cutting different types of materials. It allows for precision and accuracy in cutting and shaping wood, and can also be used for more advanced techniques such as joinery and inlay work. One of the key features of a router table is the ability to use multiple insert plates. These plates, also known as zero clearance plates, are designed to fit securely into the router table and provide a stable surface for routing.

The use of multiple insert plates on a router table offers many benefits, including increased versatility, improved safety, and reduced setup time for different routing tasks. In this blog post, we will explore the benefits of using multiple insert plates on a router table and provide tips on how to use them effectively.

Understanding Router Table Insert Plates

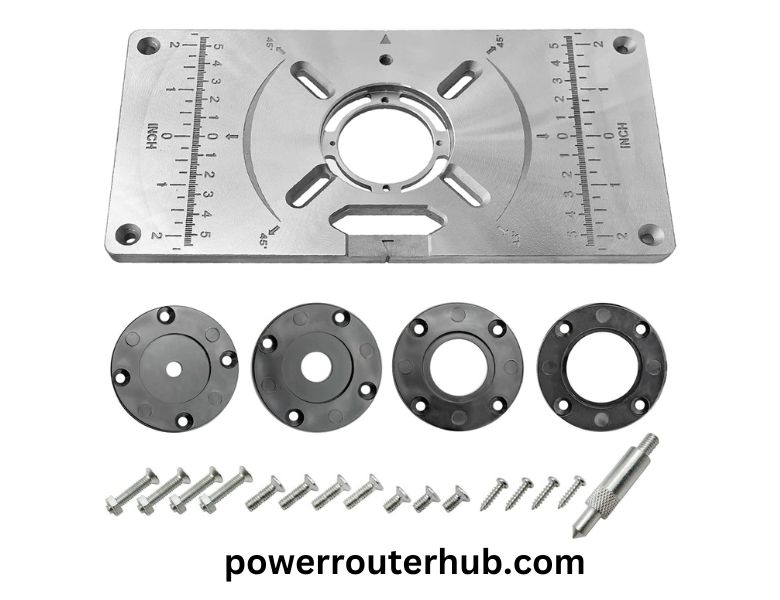

Router table insert plates are thin, flat pieces of material that are designed to fit securely into the router table. They serve as a stable surface for routing and provide a zero-clearance opening for the router bit. This means that the opening in the insert plate is the same size as the router bit, which helps to prevent tear-out and chipping on the bottom side of the workpiece. This also improves safety by reducing the chances of the workpiece getting caught in the bit.

There are different types of insert plates available for router tables, each designed for a specific purpose. Some of the most common types include:

- Zero clearance insert plates: These are the most common type of insert plate. They provide a zero-clearance opening that is the same size as the router bit, which helps to prevent tear-out and chipping on the bottom side of the workpiece.

- Laminate insert plates: These are designed to be used with laminate material. They have a smooth surface that helps to prevent chipping and cracking in the laminate.

- Solid surface insert plates: These are designed to be used with solid surface materials such as Corian or Staron. They have a smooth surface that is similar to laminate insert plates.

- Phenolic insert plates: These are made from a phenolic-resin based material, making them durable and heat-resistant. They are also resistant to warping and can handle high-speed routing.

When choosing an insert plate for a specific project, it is important to consider the type of material that will be routed and the router bit that will be used. For example, zero clearance insert plates are suitable for most general routing tasks, while laminate insert plates are better suited for routing laminate materials. The thickness of the insert plate also matters as it will affect the height of the router bit above the table.

It is important to note that, not all router tables are designed to use multiple insert plates, so it is important to check the manufacturer’s instructions and specifications before purchasing any additional insert plates.

Advantages of Using Multiple Insert Plates

Using multiple insert plates on a router table offers many advantages for woodworkers. Some of the main benefits include:

- Increased versatility: Having multiple insert plates allows for routing different types of materials with the same router table. For example, a zero-clearance insert plate can be used for general routing tasks, while a laminate insert plate can be used specifically for routing laminate materials. This increased versatility makes the router table a more versatile and valuable tool for any woodworking project.

- Improved safety and precision: Using a zero-clearance insert plate helps to prevent tear-out and chipping on the bottom side of the workpiece. This improves the safety of the routing process and also increases precision and accuracy.

- Reduced setup time: Using multiple insert plates allows for quick and easy change-out of the insert plates, reducing the setup time for different routing tasks. This can save a significant amount of time, especially when working on multiple projects or when frequently switching between routing tasks.

- Ability to use multiple router bits: Having multiple insert plates means that you can use multiple router bits with one table, which allows for more flexibility and versatility in routing.

- Increased lifespan of router bits: Having a zero-clearance plate in place reduces the amount of material that can get into the router bit, this can help to prolong the life of the router bit.

- Protection of the table: Insert plates can protect the surface of the router table from scratches, dings and other types of damage.

Overall, using multiple insert plates on a router table can help woodworkers to work more efficiently and effectively, while also improving the safety and precision of the routing process.

See Also: Router Table Safety Features

How to Use Multiple Insert Plates

Using multiple insert plates on a router table is a straightforward process, but it is important to follow the manufacturer’s instructions and guidelines to ensure proper use and avoid any potential damage to the table or router bit. Here are some general tips on how to use multiple insert plates on a router table:

- First, check the manufacturer’s instructions and specifications for the router table to ensure that it is designed to use multiple insert plates.

- Measure the size of the router bit that will be used and choose an insert plate that has a corresponding opening size.

- Make sure the insert plate is clean and free of any debris before installing it into the router table.

- Carefully align the insert plate into the router table, making sure that it is level and secure.

- Adjust the height of the router bit so that it is flush with the surface of the insert plate. This will ensure a smooth and precise cut.

- Before routing, check that the workpiece is securely clamped or held in place to prevent any movement during the routing process.

- Begin routing, making sure to keep your hands and fingers away from the router bit at all times.

- After routing, turn off the router and wait for the bit to come to a complete stop before removing the workpiece.

- Once the routing is complete, carefully remove the insert plate and store it in a safe place.

It’s important to note that, while using multiple insert plates can greatly enhance the versatility of your router table, it also adds an extra step of setup time before each routing operation. It is crucial to carefully measure and align the insert plates for optimal performance.

When working with multiple insert plates, it’s a good idea to label each one so you can easily identify it and know which one is best for a specific task. This will help you to quickly change between insert plates and reduce setup time for different routing tasks.

Conclusion

In conclusion, using multiple insert plates on a router table can greatly enhance the versatility and performance of the tool. It allows you to route different types of materials, improves safety and precision, reduces setup time, and increases the lifespan of your router bits. With a little care and attention when installing and aligning the insert plates, woodworkers can enjoy the many benefits of using multiple insert plates on their router table. It’s a great investment that can save you time and money in the long run, as well as make your routing projects more precise, accurate, and safe. It’s a highly recommended upgrade for any serious woodworker.

1 thought on “Upgrade Your Router Table with Multiple Insert Plates for Maximum Versatility”