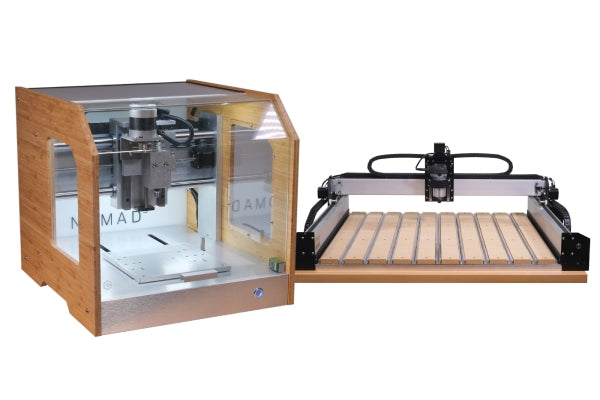

Cnc routers are great for woodworking hobbyists who want precision and speed in their woodworking projects. These machines use computer-controlled cutting tools to carve and shape wood, allowing for intricate designs and patterns.

Cnc routers come in various sizes, from small desktop models to larger industrial machines, and can be programmed to cut various materials beyond wood. They also offer benefits like faster production times, repeatability, and uniformity in cutting. However, they can be cost-prohibitive for some hobbyists, and the software used to program the machine can have a steep learning curve.

Overall, cnc routers offer a powerful tool for woodworking hobbyists looking to take their craft to the next level.

Credit: mellowpine.com

The Rise Of Cnc Routers In Woodworking

Woodworkers are continually looking for ways to make their craft more efficient without sacrificing quality. This is where the computer numerical control (cnc) router comes in. The cnc router is a machine that uses a computer-controlled system to cut, carve, and shape wood.

In recent years, its popularity in woodworking has soared. We will explore the reasons behind the rise of cnc routers in woodworking.

Evolution Of Technology In Woodworking

Woodworking technology has been evolving ever since people started working with wood. From rudimentary hand tools to the present day power tools and cnc routers, technology has made the process faster, more efficient, and more precise. The evolution of woodworking technology has brought several benefits, such as increased speed of production, higher precision, and better quality of work.

Benefits Of Using Cnc Routers In Woodworking

Cnc routers have made woodworking more accessible to people with little to no experience in carpentry. Here are some of the benefits of using cnc routers in woodworking:

- Precision and accuracy: Cnc routers can produce intricate designs with exact precision and accuracy, which is impossible to achieve with hand tools.

- Speed of production: Cnc routers offer faster production times as it eliminates the need for manual labor.

- Consistency in quality: Cnc routers provide consistent quality as the machine performs the same task repeatedly.

- Design flexibility: Cnc routers offer the freedom to create designs with complex shapes and patterns that are difficult to achieve with traditional woodworking techniques.

- Efficiency: Cnc routers require less time and effort when compared to manual woodworking techniques.

- Cost-effective: Cnc routers can reduce the overall cost of production as it increases the speed of production without sacrificing quality.

Integration Of Traditional Woodworking Techniques With Cnc Routers

Cnc routers are not replacements for traditional woodworking techniques; instead, they are complementary. Integration of traditional woodworking techniques with cnc routers allows woodworkers to create unique designs that are not possible with either method alone. Cnc routers bring precision and efficiency while traditional woodworking techniques bring a personal touch that machine work cannot replicate.

This integration brings the best of both worlds and guarantees a high-quality end product.

The rise of cnc routers in woodworking is inevitable, given the significant benefits and efficiency it brings to the craft. Woodworkers can now produce intricate designs with exact precision and accuracy faster, more efficiently, and cost-effectively. However, it is essential to note that the cnc router cannot replace traditional woodworking techniques but can integrate with them to create a personalized and high-quality end product.

Getting Started With Cnc Routers In Woodworking

Cnc routers have revolutionized the woodworking industry, bringing precision and efficiency to the process. If you’re new to cnc routers and woodworking, getting started can be a bit daunting. Here are some key points to consider as you dive into this exciting world:

Understanding The Basics Of Cnc Technology

- Cnc stands for computer numerical control. A cnc router is essentially a computer-controlled cutting machine.

- Instead of manually operating the router, you use a computer program to design your project and instruct the router on how to cut your material.

- Cnc routers can cut precisely and quickly, making them ideal for intricate designs and large-scale projects.

Selecting The Right Cnc Router For Your Woodworking Needs

- Consider the size of your projects. If you plan to work on small projects, a tabletop cnc router may be sufficient. Larger projects may require a floor-standing model.

- Think about the materials you plan to work with. Some routers are optimized for certain materials, such as wood or plastic.

- Look for reviews and recommendations from other woodworkers to find a reputable brand and model.

Safety Considerations When Working With Cnc Routers

- Always wear eye and ear protection when working with a cnc router.

- Keep loose clothing and long hair away from the machine.

- Consider using a dust collection system to reduce the amount of dust and debris in the air.

Designing And Creating Projects With Cnc Routers

Overview Of Designing With Cad Software

Before you can start creating projects with cnc routers, you need to design them first. Computer-aided design (cad) software has made it easier than ever before to design intricate and precise projects. Here are some key points to keep in mind when designing with cad software:

- Cad software allows you to create 3d models of your projects and make precise measurements.

- You can easily make changes and adjustments to your designs before sending them to the cnc router.

- There are many cad software programs to choose from, some of which are free and some that require a subscription.

Tips For Creating Cnc Router-Friendly Designs

When designing projects for cnc routers, it’s important to keep in mind the capabilities and limitations of the router. Here are some tips to help you create cnc router-friendly designs:

- Use vector-based designs, such as those created in adobe illustrator, rather than raster images, which can cause the cnc router to carve unevenly.

- Avoid designs with sharp angles or corners, which can cause the router bit to break.

- Use a consistent depth for your designs to ensure even carving, and avoid designs that require varying depths.

- Consider the size and shape of the material you will be carving, and adjust your design accordingly.

Carving, Engraving, And Inlaying Techniques With Cnc Routers

Cnc routers open up a world of possibilities when it comes to carving, engraving, and inlaying projects. Here are some techniques you can use with your cnc router:

- Carving: Use a larger router bit for larger areas and a smaller bit for more intricate areas to create depth and detail in your carving.

- Engraving: Use a v-bit and adjust the depth to create sharp, precise lines in your engraving.

- Inlaying: Use a pocketing tool to create a recess in your material, then use a different material to fill in the recess and create a decorative effect.

Designing and creating projects with cnc routers can be both challenging and exciting. Keep these tips in mind for successful design and carving with your cnc router.

Optimizing Cnc Router Operation For Higher Efficiency And Precision

Cnc routers have revolutionized woodworking, allowing hobbyists to produce precise and intricate designs with ease. However, like any machine, optimizing cnc router operation is essential to achieve higher efficiency and precision. In this section, we’ll discuss three essential aspects to keep in mind to get the most out of your cnc router: maintaining and calibrating your machine, understanding speeds and feeds, and proper tool selection and storage.

Maintaining And Calibrating Cnc Routers

A well-maintained and calibrated cnc router can dramatically improve performance and reliability. Here are a few key points to keep in mind:

- Regularly inspect your machine and its components for any signs of wear and tear, such as loose bolts or damaged bearings.

- Clean the machine’s spindle, dust collection system, and tool holder after each use.

- Check and calibrate your tool’s length offset to ensure cutting accuracy.

- Ensure that the z-axis is properly calibrated as it affects the precision of cuts.

- Lubricate all mechanical components regularly to prevent friction and extend the life of your machine.

Understanding Speeds And Feeds

The right combination of spindle speed and feed rate is essential to achieve efficient and precise cuts. Here are some key points to keep in mind:

- Spindle speed refers to how fast the router bit rotates. Set the proper spindle speed according to the material you want to cut and the router bit’s diameter.

- Feed rate refers to how fast the machine moves the router bit through the material. Selecting the right feed rate depends on the spindle speed, material, and cutting depth.

- Adjust your spindle speed and feed rate to suit the material hardness and thickness. Using a slower spindle speed and feed rate for harder materials will create cleaner cuts and prevent tool damage.

Proper Tool Selection And Storage

Choosing the right tool for the job will ensure your cuts are clean, precise, and efficient. Here are some key points to keep in mind:

- Always use the right type of cutting tool for the material to be cut.

- Keep your cutting tools sharp and in good condition. A dull tool will result in a subpar finish quality and increase the cutting time.

- Store your tools in a dry and cool space away from any moisture or direct sunlight.

- Always secure the cutting tool properly and inspect it for any signs of wear and damage before use.

By following these tips, you can optimize your cnc router operation for higher efficiency and precision. Regular maintenance, understanding speeds and feeds, and proper tool selection and storage will ensure that your cnc router produces high-quality designs and remains reliable for years to come.

Ushering Your Woodworking Hobby To The Next Level With Cnc Routers

Ushering your woodworking hobby to the next level with cnc routers

Cnc routers have been a game-changer for woodworkers, both professionals and hobbyists alike. With their precision and ability to carve intricate designs into wood, cnc routers are fast becoming the go-to tool for woodworking enthusiasts who want nothing but the best for their craft.

We’ll be exploring how cnc routers can help you expand your woodworking hobby.

Expanding Your Woodworking Business With Cnc Routers

If you’re thinking of taking your woodworking hobby to the next level and turning it into a business, then cnc routers are your best bet. Here are some ways how it can help in expanding your business:

- Cnc routers are precise and can produce high-quality woodwork faster than manual tools.

- By automating the woodworking process, you can take bulk orders and meet deadlines efficiently.

- Cnc routers are cost-effective and can save you money on labor costs.

- You can create unique designs and personalize them to your client’s specifications.

Finding Inspiration And Resources For Cnc Woodworking Projects

Cnc routers can produce almost any design you have in mind, making it possible to create unique and intricate woodwork designs. If you’re out of inspiration, there are several resources that you can use to get started:

- Check out woodworking blogs and forums that share design and project ideas.

- Follow professional woodworkers on social media platforms to get inspiration and ideas.

- Some cnc router manufacturers provide project ideas and free plans to help beginners get started.

Once you’ve chosen a design, use software programs like sketchup and autocad to create a 3d model before sending it to the cnc router.

Future Innovations In Cnc Technology And Woodworking

Cnc router technology is continuously evolving, and we can expect manufacturers to bring in more innovations to the market in the future. Some future innovations include:

- Increased precision and accuracy in carving intricate designs.

- Integration of ai technology in cnc routers to automate the designing process.

- Developing new materials that can be carved using cnc routers such as metal and plastic.

- The possibility of creating an all-in-one cnc machine that can do several carving operations in just one go.

Cnc routers have opened up a whole new world of possibilities for woodworking enthusiasts. With their precision and ability to create unique designs, they have become a must-have for any woodworking hobbyist and professional. Incorporating a cnc router in your woodworking hobby will enable you to expand your skill set, take on bulk orders, and take your hobby to the next level.

As technology continues to evolve, we can expect to see more exciting innovations in cnc routers and woodworking in the future.

Frequently Asked Questions For Cnc Routers For Woodworking Hobby

Can Beginners Use Cnc Routers For Woodworking Hobby?

Yes, cnc routers are user-friendly, and beginners can use them with ease. The software that comes with cnc routers is intuitive, making it easy for anyone to use.

How Accurate Are Cnc Routers In Woodworking Hobby?

Cnc routers are highly accurate in woodworking hobby, with a precision level of 1/100mm. The machines use computer numerical control technology, making them very precise.

Are Cnc Routers A Safer Option For Woodworking Hobby?

Yes, cnc routers are a safer option when compared to traditional woodworking methods. The machines come with safety features such as emergency stop buttons, and the operator is not in direct contact with the cutting tools.

Can I Produce Intricate Designs With Cnc Routers In Woodworking Hobby?

Yes, cnc routers are perfect for producing intricate and complex designs in woodworking hobby. The software used in the machines allows for detailed design work, resulting in very precise and intricate designs.

What Kind Of Materials Can Be Used With Cnc Routers For Woodworking Hobby?

Cnc routers can be used with a wide range of materials, including wood, plastic, and even metal. The machines have the ability to cut through thick and thin materials with ease.

Conclusion

From the aforementioned discussion, it is evident that cnc routers have revolutionized the woodworking hobby, making it more accessible and convenient for enthusiasts to bring their ideas to life. Whether you are a beginner or an experienced woodworker, there is a cnc router for everyone, offering precision, accuracy, speed, and versatility.

These machines not only streamline the creative process, but they also enable woodworkers to produce complex designs that are too hard to achieve manually. As a hobbyist, investing in a cnc router is definitely worth considering, as it can free up your time for design and finishing work while delivering projects quicker.

Remember, choosing the right cnc router for your needs can be challenging, but by considering the factors discussed in this post, you can make an informed decision and take your woodworking hobby to the next level.