Router tables are a valuable tool in any woodworking shop, offering precision and versatility for shaping and cutting wood pieces. They are commonly used for things like edge profiling, slot cutting, and mortising. However, as with any power tool, safety must be a top priority when using a router table.

In this blog post, we will take a look at the various safety features of router tables and the best practices for using and maintaining them to ensure that you can work safely and efficiently. From the guard and fence to dust collection and emergency stop, we’ll cover all the important aspects of router table safety. Whether you’re a seasoned woodworker or new to the craft, this guide will provide valuable information for ensuring a safe and successful router table experience.

Guarding

One of the key safety features of a router table is the guard. The guard is typically a clear plastic shield that surrounds the router bit and its purpose is to prevent debris and wood chips from flying out of the table and potentially hitting the operator or causing other hazards. Additionally, it also helps to protect the operator’s hands from coming into contact with the spinning router bit.

It’s important to properly adjust and use the guard to ensure maximum safety. This can be done by adjusting the guard to the correct height relative to the router bit and making sure it is securely attached to the table. It’s also important to ensure that the guard is properly aligned with the bit, so that it can effectively contain debris and chips.

When using the router table, it’s important to keep the guard in place at all times, unless you are making a specific cut that requires it to be removed temporarily. Even then, it should be reattached as soon as the cut is complete.

In summary, the guard on a router table is a critical safety feature that helps to protect the operator from flying debris and also from contact with the spinning bit. To ensure the safety, it’s important to properly adjust and use the guard, and keep it in place whenever possible.

See Also: Router Table Accessories

Fences

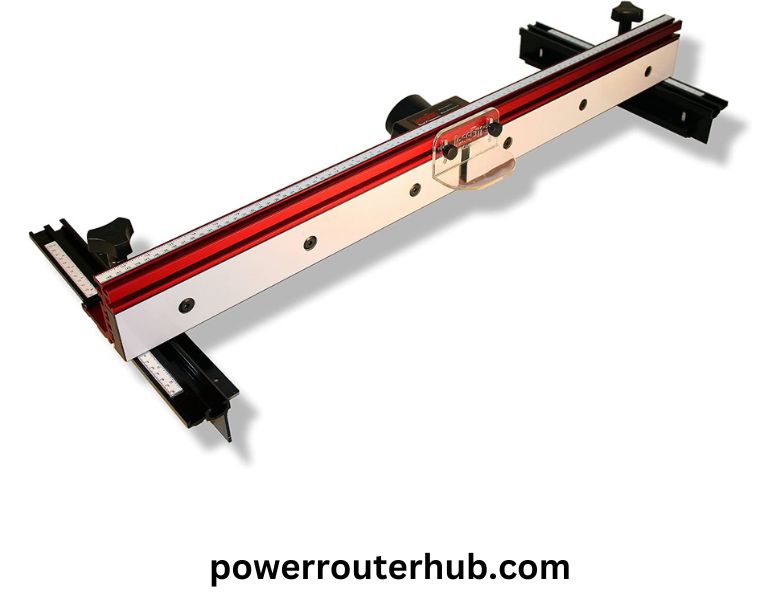

Another important safety feature of a router table is the fence. The fence is a guide that helps to keep the wood piece stable while it is being cut and also helps to guide the operator in making accurate cuts. It is typically made of metal or hard plastic and can be adjusted to different angles and positions depending on the task at hand.

To ensure maximum safety when using a router table, it’s important to properly adjust and align the fence. This can be done by adjusting the angle of the fence to match the angle of the cut and making sure that the fence is parallel to the bit. It’s also important to ensure that the fence is securely attached to the table and that it is not loose or wobbly.

When using the router table, it’s important to keep the wood piece against the fence at all times to ensure stability and control of the cut. It’s also important to use featherboards, which are devices that help to hold the wood piece against the fence, to ensure an even more stable and safe cutting.

In summary, the fence on a router table serves as a guide for accurate cuts and stability of the wood piece. To ensure the safety, it’s important to properly adjust and align the fence, keep the wood piece against it at all times, and use featherboards to ensure an even more stable cutting.

Push Blocks and Push Sticks

Push blocks and push sticks are essential safety tools that should be used when working with a router table. They allow the operator to safely guide the wood piece through the router bit while keeping hands and fingers away from the cutting area.

Push blocks are typically made of hard plastic and have a handle for grip and a flat surface to push the wood piece against the bit. Push sticks, on the other hand, are typically made of wood and have a handle for grip and a pointed end to push the wood piece against the bit.

When selecting a push block or push stick, it’s important to choose one that is the appropriate size for the task at hand and that offers a secure grip. It’s also important to ensure that the push block or push stick is in good condition, free of cracks or splinters.

When using a router table, it’s important to use a push block or push stick to guide the wood piece through the bit, keeping hands and fingers away from the cutting area. It’s also important to use appropriate hand placement and grip to ensure control and stability of the wood piece.

In summary, push blocks and push sticks are essential safety tools that allow the operator to safely guide the wood piece through the router bit while keeping hands and fingers away from the cutting area. To ensure the safety, it’s important to choose an appropriate size and condition of the push block or push stick, use it to guide the wood piece through the bit, and use appropriate hand placement and grip.

Dust Collection

Dust collection is an important aspect of router table safety, as it helps to keep the work area clean and free of debris, which can reduce the risk of accidents and also prolong the life of the tools and equipment.

Most router tables come equipped with a dust collection port, which can be connected to a dust collection system or a shop vac. This system helps to collect the dust and debris created while cutting, preventing it from becoming airborne and reducing the risk of breathing in harmful particles.

When using a router table, it’s important to make sure that the dust collection system is properly connected and functioning. It’s also important to regularly clean the dust collection system to ensure that it is functioning at maximum efficiency.

Additionally, it’s important to wear appropriate personal protective equipment (PPE) such as a dust mask or respirator to protect from inhaling harmful dust particles.

In summary, dust collection is an important aspect of router table safety as it helps to keep the work area clean and free of debris, which can reduce the risk of accidents and also prolong the life of the tools and equipment. To ensure the safety, it’s important to make sure that the dust collection system is properly connected and functioning, regularly clean the dust collection system, and wear appropriate personal protective equipment (PPE).

Emergency Stop

An emergency stop feature is a must-have safety feature on any router table. This feature allows the operator to quickly shut off the power to the router in case of an emergency, such as an accident or power failure.

Most router tables come equipped with an emergency stop button, which is typically red in color and is prominently placed for easy access. This button can be used to shut off power to the router in case of an emergency.

When using a router table, it’s important to familiarize yourself with the location and function of the emergency stop button. It’s also important to know the proper protocol for shutting off the power in case of an emergency, such as removing the plug from the outlet.

In addition to the emergency stop button, it’s important to have a plan in place for emergency situations, such as knowing the location of the nearest fire extinguisher and emergency exits.

In summary, an emergency stop feature is a must-have safety feature on any router table. This feature allows the operator to quickly shut off the power to the router in case of an emergency, such as an accident or power failure. To ensure the safety, it’s important to familiarize yourself with the location and function of the emergency stop button, know the proper protocol for shutting off the power in case of an emergency, and have a plan in place for emergency situations.

Bit Height Adjustment

Proper bit height adjustment is essential for safe router table operation. The bit height should be set so that it is just slightly above the surface of the material being cut, which will help to reduce the risk of kickback and ensure a smooth and precise cut.

Most router tables come equipped with a bit height adjustment mechanism, which allows the operator to easily adjust the height of the bit. This mechanism typically includes a crank or lever that can be used to raise or lower the bit.

When adjusting the bit height, it’s important to make sure that the router is unplugged and that the bit has come to a complete stop before making any adjustments. It’s also important to use a ruler or other measuring tool to ensure that the bit is set to the proper height.

In addition, it’s important to make sure that the bit is properly secured in the collet and that the collet is tightened to the appropriate torque to ensure that the bit does not come loose during operation.

In summary, proper bit height adjustment is essential for safe router table operation. The bit height should be set so that it is just slightly above the surface of the material being cut, which will help to reduce the risk of kickback and ensure a smooth and precise cut. To ensure the safety, it’s important to make sure that the router is unplugged and that the bit has come to a complete stop before making any adjustments, use a ruler or other measuring tool to ensure that the bit is set to the proper height and make sure that the bit is properly secured in the collet and that the collet is tightened to the appropriate torque.

Bit Change

Proper bit change is an important aspect of router table safety, as it ensures that the bit is securely in place and that the router is properly calibrated for the task at hand.

When changing the bit, it’s important to make sure that the router is unplugged and that the bit has come to a complete stop before making any adjustments. The collet should be loosened and the old bit removed, and then the new bit should be inserted into the collet and tightened to the appropriate torque.

It’s also important to make sure that the bit is the correct size and style for the task at hand, and that it is properly secured in the collet. This will help to reduce the risk of the bit coming loose during operation and causing an accident.

In addition, it’s important to check the calibration of the router before beginning a new task. This will ensure that the router is set to the correct depth and that it is properly aligned with the fence and guide.

In summary, proper bit change is an important aspect of router table safety, as it ensures that the bit is securely in place and that the router is properly calibrated for the task at hand. To ensure the safety, it’s important to make sure that the router is unplugged and that the bit has come to a complete stop before making any adjustments, check the bit is the correct size and style for the task, make sure that the bit is properly secured in the collet, and check the calibration of the router before beginning a new task.

Router Table Safety Features: What must you not do when operating a router table?

When operating a router table, it is important to avoid several things. Here are a few things you should not do:

- Do not reach over the cutting area while the router is running.

- Do not remove guards or other safety devices from the router table.

- Do not use dull or damaged router bits.

- Do not use the router table with wet hands or in a damp environment.

- Do not touch the cutter or workpiece with your hands while the router is running.

- Do not use the router table with damaged or worn out electrical cords or plugs.

- Do not operate the router table without proper training or instruction.Do not exceed the maximum speed and capacity of the router table.

- It’s very important to read the instruction manual and follow the manufacturer’s guidelines to ensure safe operation of the Router Table.

See Also Router Table Dust Collection

Conclusion

In conclusion, a router table is a powerful tool that can be used to make a wide variety of cuts and shapes in wood, plastic, and other materials. However, like any power tool, a router table can be dangerous if it is not used properly. By understanding and implementing the safety features outlined in this article, such as guarding, fences, push blocks and push sticks, dust collection, emergency stop, bit height adjustment and bit change, you can help to reduce the risk of injury and ensure a safe and successful operation.

Additionally, it’s always important to read and understand the manual and follow the manufacturer’s instructions and guidelines. With proper training, care, and attention to safety, a router table can be a valuable addition to any workshop.