The difference between upcut and downcut router bits lies in their direction of cut, surface finish, and suitability for various applications.

Upcut router bits cut in an upward direction and are best suited for roughing cuts and removing material quickly. They tend to leave a rougher surface finish and produce more vibration and noise during cutting.

Downcut router bits, on the other hand, cut in a downward direction and are best suited for finishing cuts and creating a smoother surface finish. They tend to leave a smoother surface finish and produce less vibration and noise during cutting. In this article, we will explore the differences between Upcut and Downcut router bits in more detail.

| | Upcut Router Bits | Downcut Router Bits |

|---|---|---|

| Direction of Cut | Upward | Downward |

| Chip Ejection | Upward | Downward |

| Surface Finish | Rougher | Smoother |

| Cutting Speed | Faster | Slower |

| Material Removal | More | Less |

| Cutting Depth | Deeper | Shallower |

| Vibration | More | Less |

| Noise | More | Less |

| Tool Life | Shorter | Longer |

| Application | Roughing cuts | Finishing cuts |

Key differences between the two router bits are given below:

- The direction of Cut: Upcut router bits are cut in an upward direction, while Downcut router bits are cut in a downward direction.

- Chip Ejection: Upcut router bits eject chips upward and away from the material being cut, while Downcut router bits eject chips downward and into the material being cut.

- Surface Finish: Upcut router bits tend to leave a rougher surface finish on the material being cut, while Downcut router bits tend to leave a smoother surface finish.

- Cutting Speed: Upcut router bits generally cut faster than Downcut router bits due to their design and direction of cut.

- Material Removal: Upcut router bits remove more material in a single pass than downcut router bits.

- Cutting Depth: Upcut router bits can cut deeper into material than Downcut router bits due to their direction of cut and ability to remove more material.

- Vibration: Upcut router bits tend to produce more vibration during cutting due to their direction of cut.

- Noise: Upcut router bits tend to produce more noise during cutting due to their direction of cut and faster cutting speed.

- Tool Life: Upcut router bits tend to have a shorter tool life than Downcut router bits due to the increased stress on the cutting edge.

- Application: Upcut router bits are generally used for roughing cuts and removing material quickly, while Downcut router bits are used for finishing cuts and creating a smoother surface finish.

Upcut Router Bits

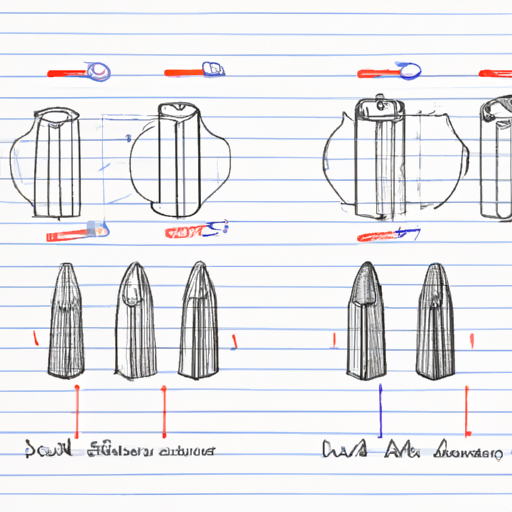

Upcut router bits, also known as up spiral router bits, are designed to cut upwards through the wood. The cutting edge of the bit is angled upwards, and the flutes (or grooves) on the bit are also angled upwards. This allows the bit to quickly remove material as it rotates, and the chips are carried upwards and away from the cutting edge.

One of the advantages of using Upcut router bits is their ability to quickly remove material. The upward-cutting action of the bit allows it to efficiently clear out any excess wood, making it a good choice for roughing out a shape or for making deep cuts. Upcut router bits also tend to prevent chips from getting stuck in the bit, which can cause the bit to overheat and dull quickly.

However, there are also some potential drawbacks to using Upcut router bits. The upward cutting action of the bit can cause splintering on the top surface of the wood, resulting in a rougher finish. This can be mitigated by using a slower feed rate and by making multiple shallow passes instead of one deep cut.

Downcut Router Bits

Downcut router bits, also known as down spiral router bits, are designed to cut downwards through the wood. The cutting edge of the bit is angled downwards, and the flutes (or grooves) on the bit are also angled downwards. This allows the bit to create a smoother top surface on the wood as it rotates.

One of the advantages of using Downcut router bits is their ability to produce a smoother finish on the top surface of the wood. The downward-cutting action of the bit helps to prevent splintering, resulting in a cleaner and more polished look. Downcut router bits also tend to prevent chips from lifting, which can cause tear-out on the bottom surface of the wood.

However, there are also some potential drawbacks to using downcut router bits. The downward cutting action of the bit can cause the bit to have a slower cutting speed, as it is not as efficient at removing material. This can make the cutting process longer and more time-consuming. Downcut router bits can also cause a tear-out on the bottom surface of the wood if the feed rate is too fast or the material is not properly supported.

Choosing the Right Router Bit

The type of router bit to use depends on the specific project and the desired results. Both Upcut and Downcut router bits have their own advantages and disadvantages, and the right choice will depend on the project at hand.

When choosing between Upcut and Downcut router bits, there are several factors to consider. The type of wood, the thickness of the material, and the desired finish are all important considerations. For example, if you are working with softwood, an Upcut router bit may be a good choice for quickly removing material, while a Downcut router bit may be better suited for hardwood to prevent splintering.

It is often helpful to experiment with both types of router bits to determine which works best for a particular project. Some woodworkers may even use both types of router bits in a single project, using an upcut router bit for roughing out the shape and a Downcut router bit for the final pass to create a smooth finish.

What is an Upcut Bit Used For?

An Upcut bit is a type of drill bit used for cutting and drilling into materials such as wood, plastic, and aluminum. It is designed to cut upwards, as opposed to a standard bit which cuts straight through. Upcut bits are used for creating clean edges and for removing material quickly and efficiently. They are also ideal for making pocket holes, as the upward-cutting action allows the bit to easily clear out material from the hole.

Why Use a Downcut Router Bit?

A Downcut router bit is an incredibly useful tool for woodworking projects. It is designed to cut along the grain of the wood, allowing for smooth, precise cuts. This is particularly useful when you need to create straight edges, such as in end grain or edge banding.

Downcut router bits also reduce tear-out on the underside of the cut, which is often a problem when cutting with a regular Upcut router bit. This makes them ideal for finishing projects, as they create a much cleaner cut.

FAQs on the Difference between Upcut and Downcut Router Bits

What is the Difference Between Upcut and Downcut Flush Trim Bits?

The main difference between upcut and downcut flush trim bits is the direction of their cutting action. Upcut bits lift material away from the workpiece surface, while downcut bits push material down and against the surface.

What is the difference between Upcut and Downcut bit CNC?

The main difference between Upcut and Downcut CNC router bits is their cutting direction. Upcut bits remove material upwards from the workpiece, while Downcut bits push material downwards.

Difference Between Upcut and Downcut router bit vs. Spiral Bit

The main difference is cutting direction: upcut and downcut router bits have linear cutting paths, while spiral bits have a spiral-shaped cutting action.

When To Use Upcut Spiral Router Bit

Use an upcut spiral router bit when you want to efficiently remove chips and debris from the workpiece, preventing overheating and ensuring a clean top surface finish.

Final Words

In conclusion, understanding the differences between Upcut and Downcut router bits is important for achieving the desired results in woodworking projects. Choosing the right router bit for the job can make a big difference in the quality of the finished product, and the potential benefits of using both types of router bits in different situations should not be overlooked.

Related Articles: Router Table vs Handheld Routers

1 thought on “Difference between Upcut and Downcut Router Bits”